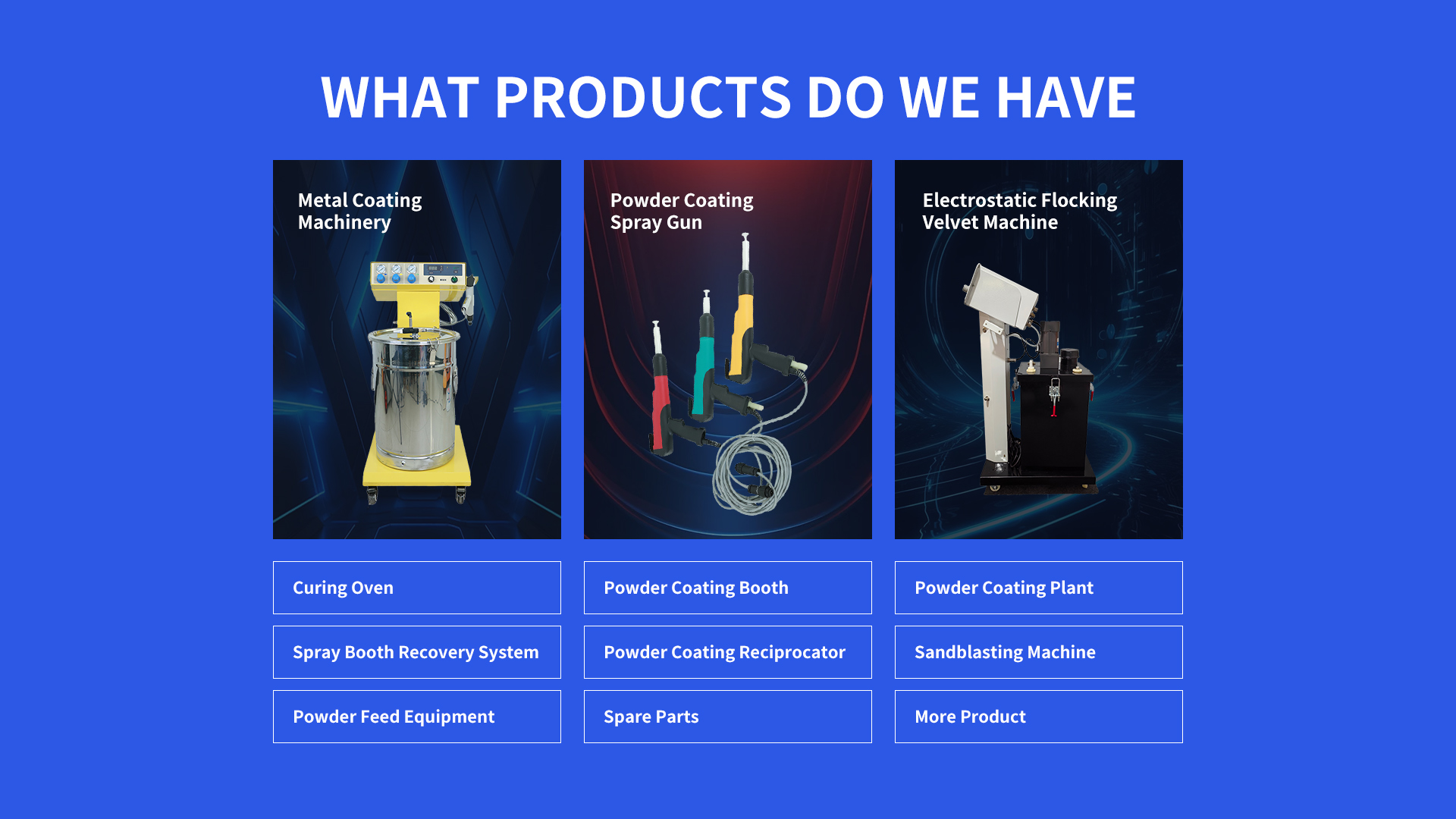

1. Electrostatic Powder Spraying Equipment Overview and Components

Electrostatic Powder Spraying Equipment applies electrically charged powder particles to grounded surfaces, ensuring efficient adhesion. Core components include an electrostatic spray gun, powder hopper, high-voltage generator, conveyor system, and curing oven. Advanced models feature robotic arms for precision, IoT sensors for real-time adjustments, and powder recovery systems to minimize waste.

2. Industrial Applications of Electrostatic Powder Spraying Equipment Systems

Widely used in automotive manufacturing (car parts, wheels), aerospace (aircraft components), and appliance production (refrigerators, ovens), these systems deliver uniform, corrosion-resistant finishes. They are also ideal for coating architectural metals, furniture, and electronics enclosures, offering durability and aesthetic versatility.

3. Electrostatic Powder Spraying Equipment Pricing

Prices range from 20,000∗∗forsemi−automatedsystemsto∗∗400,000+ for fully robotic lines. Entry-level manual guns cost 1,000–5,000, while high-end automated setups with powder recycling and IoT capabilities drive higher costs. Budget for maintenance, energy consumption, and powder materials.

4. Best Practices for Operating Electrostatic Powder Spraying Equipment

Pre-treat surfaces via sandblasting or chemical cleaning.

Set electrostatic voltage to 60–100 kV based on powder type.

Maintain a 6–12 inch spraying distance for even coverage.

Cure coated parts at 170–210°C for 10–20 minutes.

Clean nozzles and filters daily to prevent clogs.

5. How to Select Electrostatic Powder Spraying Equipment

Evaluate production volume, part complexity, and coating requirements. For high-throughput industries, prioritize robotic systems with multi-axis control. Check certifications (CE, ISO 9001) and energy efficiency ratings. Ensure suppliers offer technical support and spare parts availability.

6. Safety Measures for Electrostatic Powder Spraying Equipment Systems

Operate in well-ventilated, explosion-proof environments. Use NIOSH-approved respirators, anti-static gloves, and goggles. Ground all equipment to prevent electrostatic discharge. Conduct monthly inspections of electrical systems and emergency shutdown protocols.

7. Cost Efficiency and Design Rationale

Electrostatic systems reduce material waste by 30–50% compared to traditional methods. Automated lines achieve 95% first-pass yield, minimizing rework. Energy-efficient ovens with heat recovery cut power costs by 25%, ensuring ROI within 18–24 months.

8. FAQs About Electrostatic Powder Spraying Equipment

Q: How does electrostatic spraying improve coating efficiency?

A: Charged powder particles adhere better, reducing overspray and waste.

Q: What maintenance ensures long-lasting equipment?

A: Daily cleaning of guns and quarterly oven calibration prevent downtime.

Q: Can these systems coat non-conductive materials?

A: Yes, using conductive primers or specialized powders.

Q: Are eco-friendly powders compatible?

A: Yes, VOC-free powders align with global environmental standards.

Q: What industries benefit most from electrostatic spraying?

A: Automotive and aerospace sectors prioritize its precision and durability.

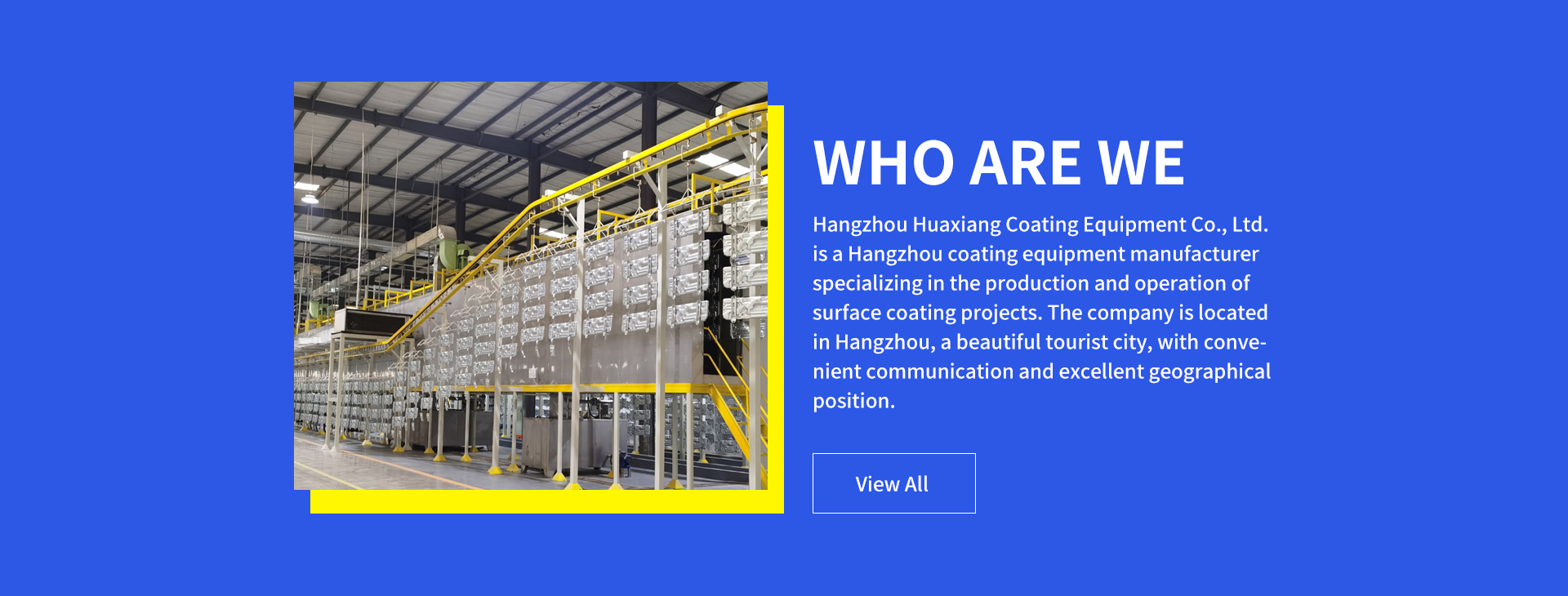

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com